|

|

#1 |

|

Участник

|

Sumit Potbhare: Retail Inbound Value-added Services or Prep in D365| Approach to D365 for Commerce with Adv WH Mgmt

Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

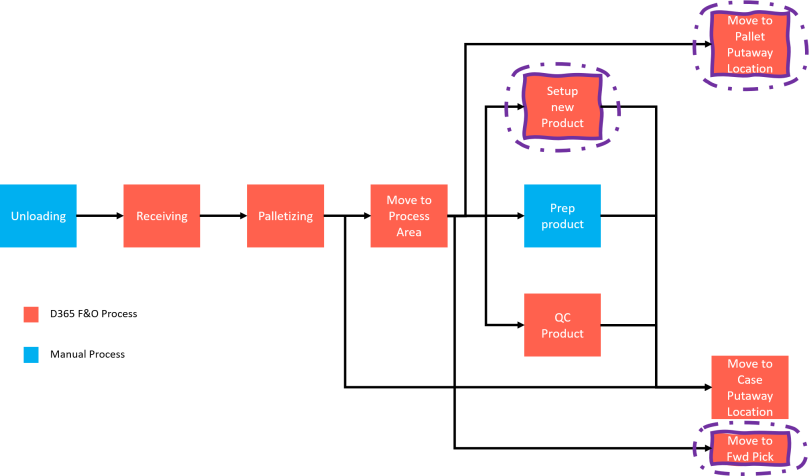

============== Hi Guys, Hope you have read my previous post where we talked about the quality control and how that product is received, directed, and also what happens once it gets there because there’s a lot of D365 FO functionality around processing QC samples. In this blog, we going to talk about prep, or inbound value-added services, because it is a significant processing area in many Retail Warehouses where we will look at how to receive and palletize it. We are going to see two scenarios:

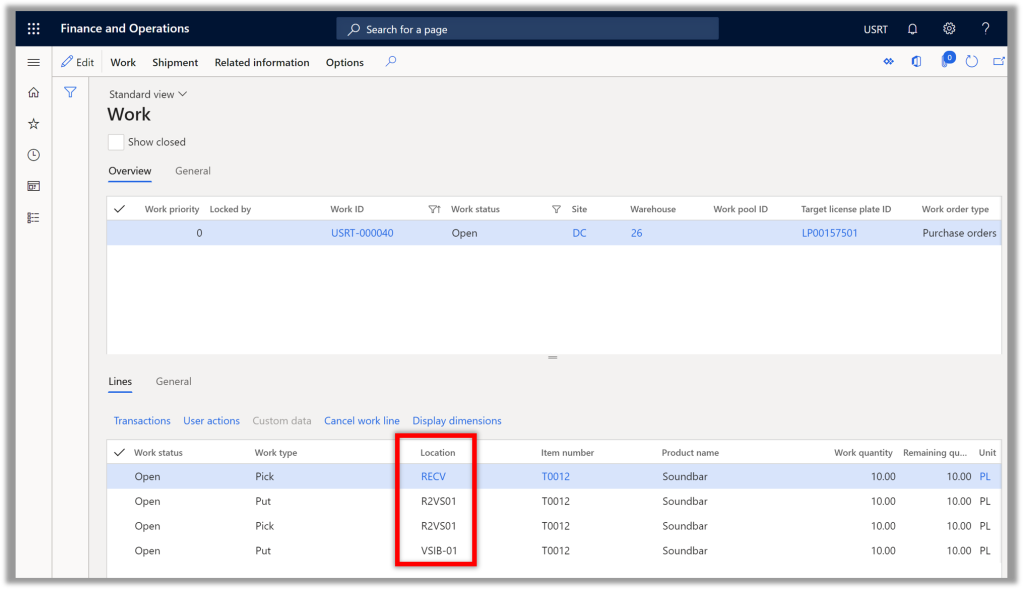

There’s a couple of different ways that product can get to the prep area. It can be system directed; that is, the SKU can be set up in such a way that every time it comes in, it has to go there. It can also be user directed. There’s a couple of different ways that product can get to the prep area. It can be system directed; that is, the SKU can be set up in such a way that every time it comes in, it has to go there. It can also be user directed. System directed to Prep Let us talk about the products that have to be system directed to prep first. Navigate to Product Information Management > Products > Released products and look up this particular product and see how through the use of filter codes we can get this product to the prep area every time it comes in the building. Navigate to Warehouse tab and here you will see two filter codes that is attached to this particular item, We have the first filter code set to PREPSKU. This means that every time this SKU comes in, it needs to go to prep. And in the second code we have listed what activity needs to happen to it once it gets there.  Now, this can be used in addition to a form or something that may be attached to the case to indicate what needs to be done to it. But this information can be captured in the system so that we know what activity it has to undergo every time it arrives there. Now let us take a look at how it will automatically get diverted to the prep area, when it’s received. Now, this can be used in addition to a form or something that may be attached to the case to indicate what needs to be done to it. But this information can be captured in the system so that we know what activity it has to undergo every time it arrives there. Now let us take a look at how it will automatically get diverted to the prep area, when it’s received. Navigate to the Procurement and sourcing > All purchase orders. Create a new purchase order for Soundbar for 20 pallets of 50 units each. Each pallet quantity comes in a form of cases which is then transferred to Pallet during palletization. Copy the PO 001575 and now let’s go over and start the process of receiving.  So imagine that the truck is backing into the door and we start pulling these cases off, and we have a case of PO 001575 that comes down to us at the receiving station. So we get into mobile device and select Receive License Plates. So imagine that the truck is backing into the door and we start pulling these cases off, and we have a case of PO 001575 that comes down to us at the receiving station. So we get into mobile device and select Receive License Plates.  Remember, we don’t know whether this is a product that has to go to prep every time it comes in or not. There’s no way for us to physically identify that on the case beforehand. So we just treat it like it’s a regular case that’s going back into case storage. So we enter the PO 001575, and scans the SKU number. He knows he has to 10 in this particular instance. And where do we want to send it? Well, we are just assuming that this is a regular item, so we will send this to the case storage area by selecting disposition code as ToPACase. And then we got to indicate what license plate is this sitting on and we scan LP00157501. And so it’s now been received.  Now, what’s happened in the background that you don’t see here is the system has checked that particular product and found that it has a filter code and it says PREPSKU, so it knows that this needs to go to prep, despite the fact that we told it to go to Case Storage. We have done that without knowing it has that filter code set because there’s no way the receiving person could see that. So let’s see if the work created reflects what the system should have done. Now, what’s happened in the background that you don’t see here is the system has checked that particular product and found that it has a filter code and it says PREPSKU, so it knows that this needs to go to prep, despite the fact that we told it to go to Case Storage. We have done that without knowing it has that filter code set because there’s no way the receiving person could see that. So let’s see if the work created reflects what the system should have done.

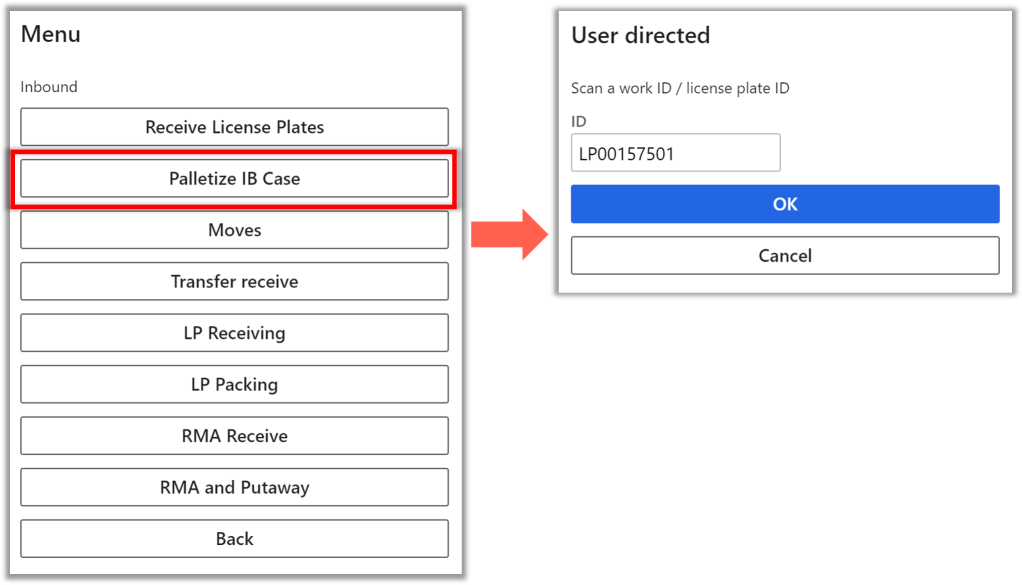

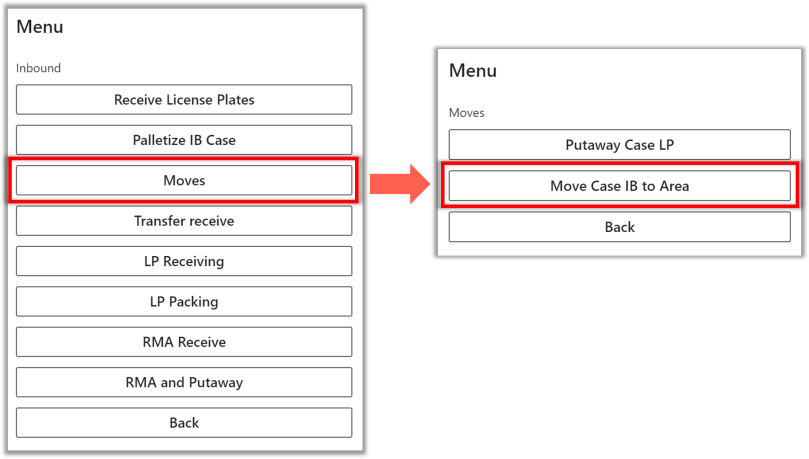

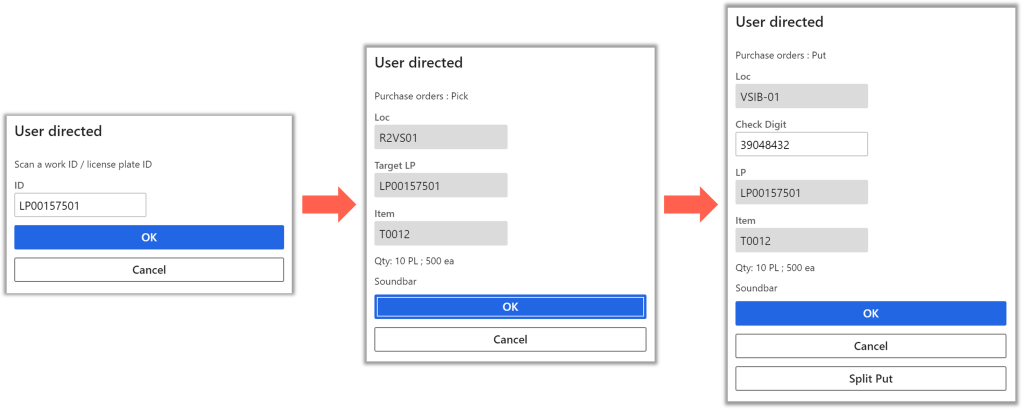

So now why don’t we go ahead and finish this part up, and we’ll palletize it. So let us go back to the mobile device terminal. Choose Palletize IB Case mobile device menu item that’s specially designed for Palletizing and enter the License plate LP00157501. So now why don’t we go ahead and finish this part up, and we’ll palletize it. So let us go back to the mobile device terminal. Choose Palletize IB Case mobile device menu item that’s specially designed for Palletizing and enter the License plate LP00157501. And you can see that it’s confirming that is this the one you got? Click OK. So it says that particular product since it needs to go to Prep, you need to put it into the Prep staging location or palletizing location there at the dock door. So I just need to type in the location check digit. And probably in the actual implementation, you’ll use a check digit that is printed on the wall as a barcode to confirm that you put it in the correct location.  The last step of this process, we have to get it to the inbound side of the value-added services area. To do that, we go into the Moves menu in the mobile device, and choose Move case inbound to area menu item specially designed to move license plates to different staging Inbound locations. The last step of this process, we have to get it to the inbound side of the value-added services area. To do that, we go into the Moves menu in the mobile device, and choose Move case inbound to area menu item specially designed to move license plates to different staging Inbound locations. And we envision that there’s a pallet at the Prep staging location with lots of cases that need to go to prep along with an orange cone. So if we are that material handling guy and we see that cone’s there, so we go over to that pallet and see there’s also this nice bright orange placard that says prep on the side of it in addition to that cone. So I know this is going to prep. So I drive that pallet over to prep. And when I get there, I have to transfer each of those cases into the prep area. We need to type in the license plate LP00157501. And it recognizes it and it says, please scan the location you’re dropping it off in. So that’s VSIB01 and we confirms by entering the check digit and that’s it. And we envision that there’s a pallet at the Prep staging location with lots of cases that need to go to prep along with an orange cone. So if we are that material handling guy and we see that cone’s there, so we go over to that pallet and see there’s also this nice bright orange placard that says prep on the side of it in addition to that cone. So I know this is going to prep. So I drive that pallet over to prep. And when I get there, I have to transfer each of those cases into the prep area. We need to type in the license plate LP00157501. And it recognizes it and it says, please scan the location you’re dropping it off in. So that’s VSIB01 and we confirms by entering the check digit and that’s it. So now we have received our case, not knowing that it always needs to go to prep, and yet the system has picked it up and directed the material handler to take it there. So it’s now comfortably resting in the prep area. So now we have received our case, not knowing that it always needs to go to prep, and yet the system has picked it up and directed the material handler to take it there. So it’s now comfortably resting in the prep area. User directed to Prep The other way an item can get to Prep area is by user directed. The receiving associate can look at a case and say, there’s something wrong with this. We really need to fix it in some way. Maybe we need to stick a label on the outside or maybe it’s a box that’s been crushed and so it needs to be reboxed. Let us talk about how D365 FO complies with that second requirement, with the user-directed cases that are going to prep. Navigate to the Procurement and sourcing > All purchase orders. Create a new purchase order and enter the lines on the PO. We are going to order just one line, Mesh BMX Gloves, and it will be for 100 quantity. Hit refresh or Save to get that PO number because we want to use that in the receiving process, so it’s PO 001576.  So imagine that truck backs into the door of the warehouse, we throw it open and start unloading cases. And we are standing there in front of the receiving station, and then this case comes to us that looks all beat up. It’s really something’s wrong with it. It looks like it’s been crushed somewhat, and we are not putting that up in the regular reserve area or the case storage area. Because if somebody puts another box on top of it, it might slide off and hit somebody down below. So when we receive this product, we select Receive License Plates and enter in the PO 001576 followed by product and quantity. But here we are going to give it a different kind of disposition code. Instead of sending it back to case storage, we want it to be reboxed. So we choose the Prep RB disposition code. Scans the license plate LP00157601. So then it flows on to the palletizing person who’s going to scan it, and they’re going to end up realizing it needs to go to prep. So imagine that truck backs into the door of the warehouse, we throw it open and start unloading cases. And we are standing there in front of the receiving station, and then this case comes to us that looks all beat up. It’s really something’s wrong with it. It looks like it’s been crushed somewhat, and we are not putting that up in the regular reserve area or the case storage area. Because if somebody puts another box on top of it, it might slide off and hit somebody down below. So when we receive this product, we select Receive License Plates and enter in the PO 001576 followed by product and quantity. But here we are going to give it a different kind of disposition code. Instead of sending it back to case storage, we want it to be reboxed. So we choose the Prep RB disposition code. Scans the license plate LP00157601. So then it flows on to the palletizing person who’s going to scan it, and they’re going to end up realizing it needs to go to prep.  Let us look at the work that’s been created for this. Navigate to Warehouse Management > Work > Inbound > Open Purchase Work. Select the Open Work for PO 001576. And there we can see that it’s now suggesting that this needs to be palletized at R2VS01, which is the palletizing location for all the product that needs to go back to the prep area. And then from there it’s going to move on to prep. Let us look at the work that’s been created for this. Navigate to Warehouse Management > Work > Inbound > Open Purchase Work. Select the Open Work for PO 001576. And there we can see that it’s now suggesting that this needs to be palletized at R2VS01, which is the palletizing location for all the product that needs to go back to the prep area. And then from there it’s going to move on to prep. We’ll go back to the mobile device terminal, we’ll pretend that we’re the palletizing person and we’ll scan that box with the license plate LP00157601, it says please put that in R2VS01. That’s what we do, we scan that location check digit. And so now it’s resting where it’s supposed to be. We’ll go back to the mobile device terminal, we’ll pretend that we’re the palletizing person and we’ll scan that box with the license plate LP00157601, it says please put that in R2VS01. That’s what we do, we scan that location check digit. And so now it’s resting where it’s supposed to be. And it will just sit there until we get a bunch of other cases that need also to go to prep, and then we’ll put a cone on it and material handler will come along and pick it up and take it there. So I hope you understand now that D365 FO has no problem with recognizing a product and moving it to the prep area for both scenarios, the system-directed prep and the user-directed prep. And it will just sit there until we get a bunch of other cases that need also to go to prep, and then we’ll put a cone on it and material handler will come along and pick it up and take it there. So I hope you understand now that D365 FO has no problem with recognizing a product and moving it to the prep area for both scenarios, the system-directed prep and the user-directed prep. Lastly let us go to the Prep location and see what need to be prepped back here. A Prep operator is working on a prep activity right now. She needs to know what do I do to a case that shows up in prep. She needs to be able to look that up in the system or he needs some other way to know what it is that he needs to do to the merchandise that’s in that box. Well, what we propose is a very simple solution, and that’s just when any product needs to go back to prep, just attach a label, it doesn’t have to be a big label, it can be a small label, but the label lists all the different prep activities and just check off those that apply to that box so that when it gets back here, she can look at this and know exactly what she needs to do.  So this is a very practical solution to a very simple problem. And I would encourage you to use this as opposed to trying to look for some systemic type of solution. So this is a very practical solution to a very simple problem. And I would encourage you to use this as opposed to trying to look for some systemic type of solution. So I hope you got the understanding of how the products are routed to Prep area or Inbound value added service area using D365 FO.  In our next blog we will quickly go through other destinations in the Inbound process and how that can be achieved in D365 FO. In our next blog we will quickly go through other destinations in the Inbound process and how that can be achieved in D365 FO.Feel free to reach out for any clarifications. If you like my blog posts then comment and subscribe to the blogs. Join 98 other followers Subscribe #RetailDAXing #D365Commerce Disclaimer: The information in the weblog is provided “AS IS”; with no warranties, and confers no rights. All blog entries and editorial comments are the opinions of the author. Credits: Microsoft Learn, Microsoft Docs Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

__________________

Расскажите о новых и интересных блогах по Microsoft Dynamics, напишите личное сообщение администратору. |

|

|